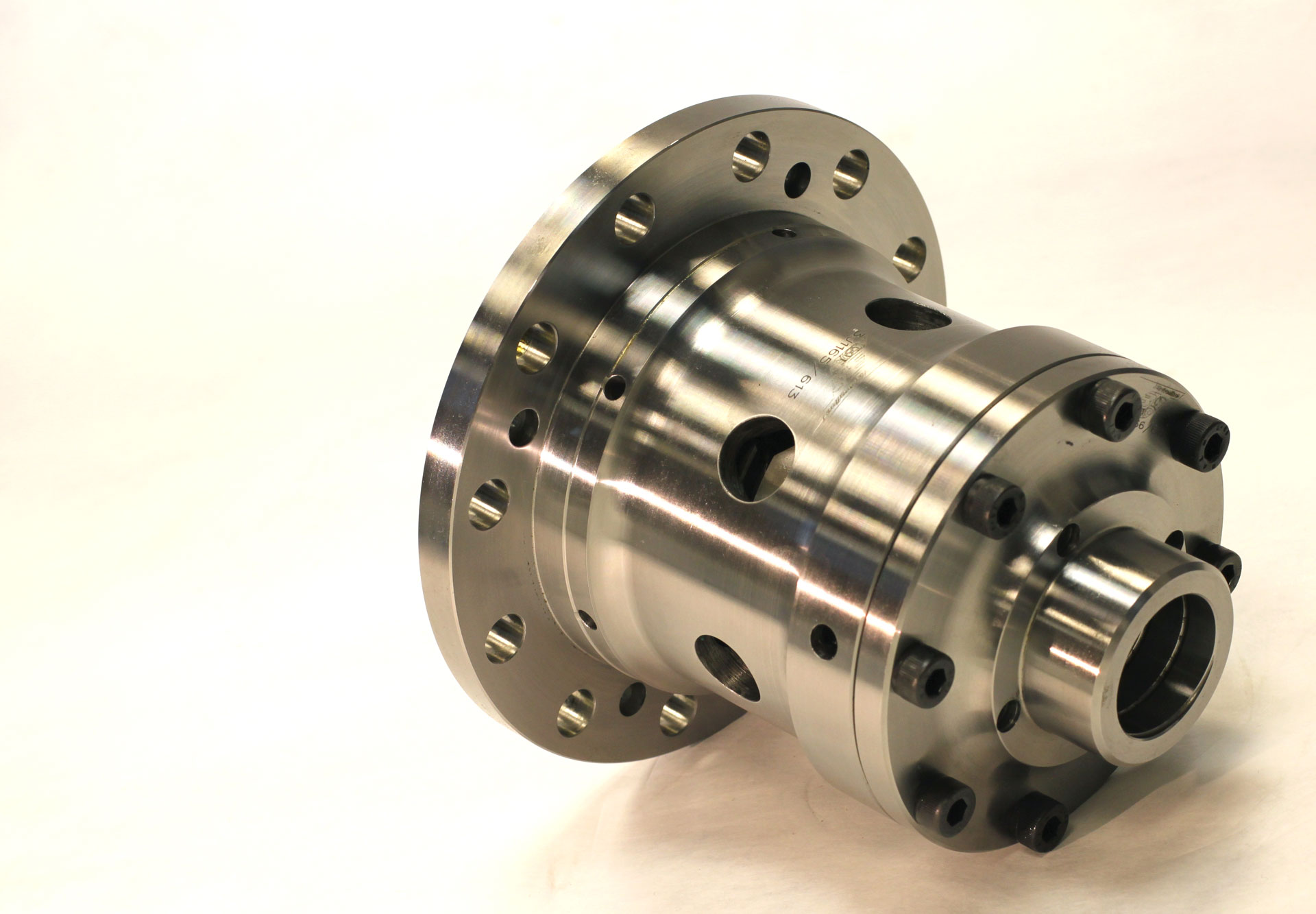

3J Driveline Limited Slip Differentials

Almost every car has at least one differential in their driveline. In basic terms a differential in a 2wd car is used to manage wheel speed differences whilst taking a corner.

Imagine a small circle inside a big circle. A lap of the smaller circle will take a lot less time to complete than a lap of the big circle. In order to complete a lap of both circles in the same time, you'd either have to go really slowly around the small circle, or really fast around the big circle.

The same is true of the wheels on your car in a corner. As you take a corner in the inner wheel will have less distance to travel than the outer wheel and as such the inner wheel will also be turning at a lower speed. If they both had the same speed, it would not be easy to take that corner and you would have a lot of understeer as they would both be fighting to travel at the same speed and will basically want to go in a straight line.

The standard "open" differential is ideal in most factory cars, but is far from ideal for getting the best out of your car. It will always transmit the same amount of torque to both wheels - ideal whilst both wheels have 100% grip as they both have 100% of the torque that the engine is delivering too them. But, put one of those wheels in a situation where it can slip - for example on some ice - if it only took a tiny amount of torque to make that wheel turn, exactly the same amount of power would be sent to the wheel that isn't on ice. Hence why you'll get one wheel spinning and one not doing anything. The same theory can be applied to cornering. As the weight of the vehicle is transferred and the tyre on the inside begins to be lifted off of the ground, the amount of engine power required to make it turn is significantly reduced and so the amount of power sent to the outside "loaded" wheel, will be exactly the same. At which point, it would't matter if you had 50bhp or 500bhp, as none of it would be getting to the wheel with any grip.

To get around this an LSD can be fitted. A LSD, or limited slip diff, does as it says on the tin - limits the amount of slip of that inside wheel. It does this by essentially transferring torque directly from the housing to the side gears and thus bypassing the actually differential bevel gears.

Whether it's by the traditional method of "clutch plates", or the more contemporary method of an additional set of bevel gears, the end result is essentially the same.

Helical or Plate-Type LSD?

If you want more traction and a unit that you can fit and forget, with no maintenance, a 3J Driveline Fast Road NXG torque-biasing unit is for you. It is smooth and silent in use and produces no additional noise when compared directly to a standard "open" differential. You'll notice an increase in traction (though it never fully locks) but that's all you'll notice. This is why we call it our Fast Road NXG and why it proves a popular option for road cars. In particular front-wheel drive cars.

For those looking for a more aggressive differential, that can fully lock the driven wheels, a plated LSD is the unit for you.

A 3J Driveline NXG Performance Plate-type LSD can be set up to perfectly suit the needs of the driver. Our expert engineers can fine tune ramp angles and pre-load to control the amount of lock, and how it's delivered, under both acceleration and braking. Because there are moving parts, it will require a degree of maintenance and servicing. It can be set up for road use but noise, slight wheel judder and lack of smoothness when turning at low speed are an inherent trait of a plated LSD. Though if set up correctly in the CWP, the 3J NXG units are quieter than many. We also have a sintered plate option to further reduce this noise. The use of recommended LSD oils will also serve to reduce this noise without effecting the operation of the differential.

Our experts are happy to advise you on what's best suited to you, but feel free to read the below explanations of how each type of diff works.

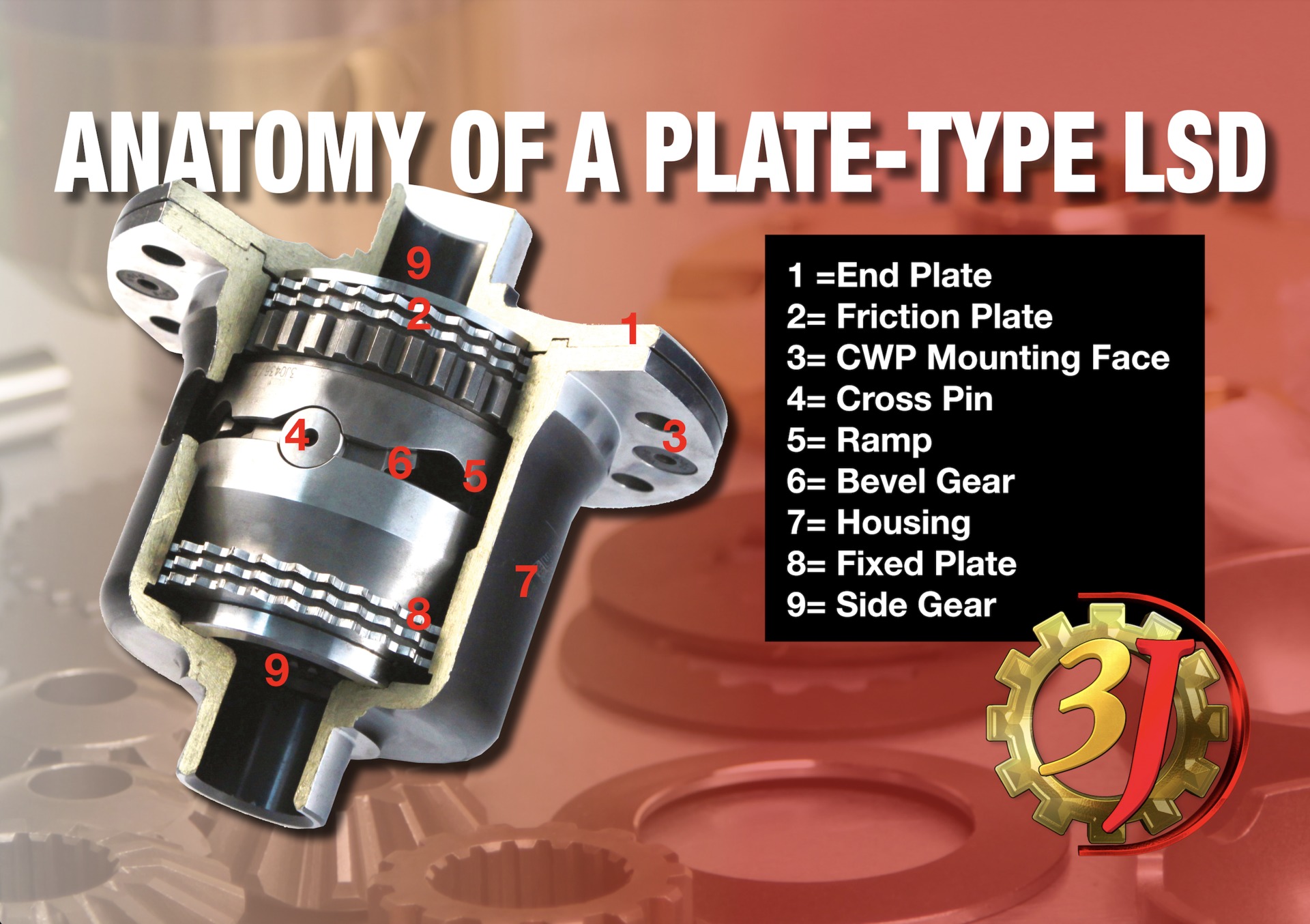

How Does a Plate-Type LSD Work?

A plate type LSD is chosen for applications where the driver requires the driven wheels to lock together to some degree. The amount of lock that occurs, and the speed at which this happens can be fine-tuned in how the diff is set up.

Under load (whether acceleration or deceleration) the cross pin rides up the ramp, which acts upon the friction plates essentially compressing them and locking either side of the differential together (which ultimately connects to your halfshafts/driveshafts).

PRE-LOAD EXPLAINED

The fixed plates and friction plates produce an axial loading together. This provides a small amount of friction which in turn locks the side gear to the differential housing when the amount of torque being transmitted is very low. Without this, none of the drive torque would be applied to the wheel that is not spinning. The pre-load is the starting point of the plate-type limited slip differential.

The bevel gears (planet pinions) have a tendency inside the differential cage to force the side gears (bevel sun gears) outwards. The additional outward force exerted by the bevel pinions when one wheel starts to spin is then transmitted to the clutch plate pack. This causes both sets of plates to be squeezed together and as a result essentially locks the side gears to the housing.

The higher the pre-load installed into the differential, the less effort is required to compress the plates and lock up the unit.

RAMP ANGLES EXPLAINED

When more torque arrives, the clutch pack is loaded further. As this power is applied (whether it's direct power or the torque created as a result of engine braking), the pressure applied to the bevel gear shaft will force the pressure rings to effectively slide outwards towards the driveshafts. As a result of this the clutch plates are compressed together, which increases the locking effect.

The lower (or shallower) the ramp angle, the higher the force outwards will be. The steeper the ramp, the lower the force will be. Put simply, the pin cannot ride up a 90 degree ramp angle and as such won't apply any more pressure to the clutch plates than the pre-load that is in-built. This ramp angle is usually found on the deceleration side of fast road differentials or units that are used in vehicles for tight, twisty, sprints.

On the contrary, the pin will easily travel up a 25 degree ramp angle and as such will increase the locking effect.

Choosing the right pressure angle depends on a lot of things - the vehicle's weight, dimensions, engine torque, what it's being used for, and much more.

1-WAY vs 1.5-WAY vs 2-WAY

A 2-way LSD is basically a unit that has two identical ramps for acceleration and deceleration, the most basic of which would be 45/45 (2-Way) which roughly equates to around 25% lockup in both driving and coasting conditions. It offers a good balance and will be predictable in its performance. With light pre-load this set-up would still see a degree of wheelspin, but significantly less than an open unit. The amount of wheelspin can be reduced by increasing the pre-load.

Making the ramp angles shallower will, in turn, make the differential more aggressive. Aggressive ramp angles are favoured by those that want to make the most of weight transfer on turn in as the wheels will be trying to lock decelerating towards the apex, as well as accelerating from it.

A 1.5 Way setup is generally considered more versatile and user friendly. As a rule they will have a shallower ramp angle on the drive side than the deceleration side. 35/45 (1.5 Way) by example will give you approximately 40% lock under acceleration and 25% lock when coasting. Many people opt for a 1.5-way as it enables more aggressive cornering and better grip on exit, without the vehicle becoming unsettled when turning in.

1-Way units are typically used in front-drive cars, although fast-road rear-drive applications will also run this configuration. By example a 40/90 ramp angle (1-Way) will be used where the best possible turn-in and exit grip is desired, and no lockup under deceleration is required.

CHOOSING THE RIGHT SETUP FOR YOU

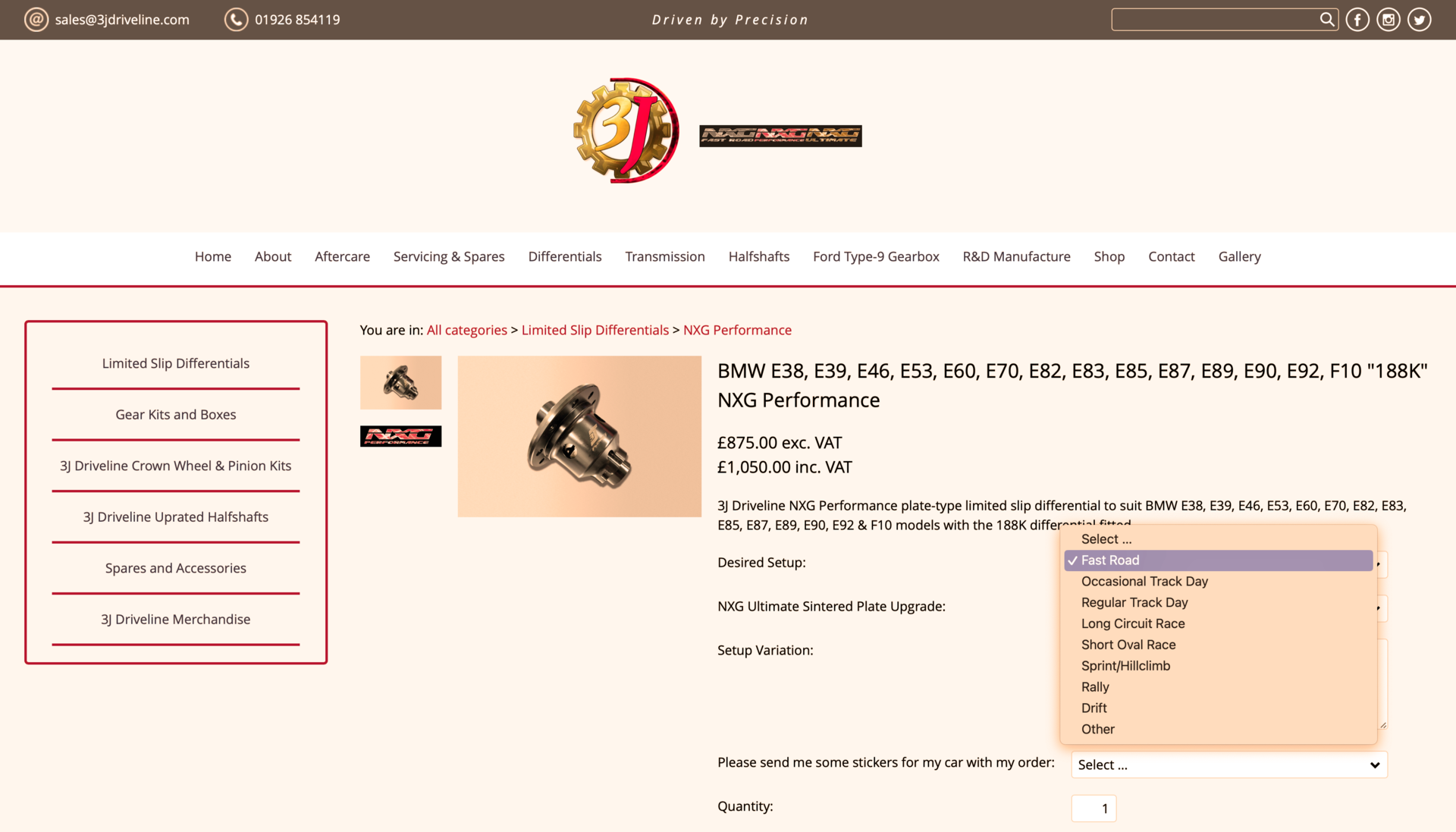

Because our differentials have a large spectrum of possible set-up configurations, we have tried to make it easier for you to choose the right unit for you when purchasing one of our limited slip differentials through our online shop.

When purchasing the unit you will be able to select from a number of setup options in the drop-down menu as illustrated below. These options are based on the most common applications that we sell.

If you are curious as to what these settings equate to, it does often depend on the weight and power of the vehicle into which they are being installed, however below are the approximate ramp angles and pre-loads for each. If you require a specific setup, you can notify us by selecting "Other" at this stage and we will contact you after checkout to discuss your requirements.

FAST ROAD - 55/90 Ramps 25-35 Lbs/Ft (34-47NM) Pre-load

- OCCASIONAL TRACK DAY 45/90 Ramps 25-35 Lbs/Ft (34-47 NM) Pre-load

- REGULAR TRACK DAY 45/90 Ramps 35-40 Lbs/Ft (47-54NM) Pre-load

- LONG CIRCUIT RACE 45/90 or 30/90 Ramps 65-75 Lbs/Ft (88-102NM) Pre-load

- SHORT OVAL RACE 45/90 Ramps 50-55 Lbs/Ft (68-75NM) Pre-load

- SPRINT/HILLCLIMB 45/90 Ramps 60-65 Lbs/Ft (81-88NM) Pre-load

- RALLY 35/90 Ramps 65-80 Lbs/Ft (88-109 NM) Pre-load

- DRIFT 45/45 Ramps 40-50 Lbs/Ft (64-68 NM) Pre-load

PLATE TYPE LSD FREQUENTLY ASKED QUESTIONS

Q: Why is my plate-type differential noisy?

A: The very nature of a plate type differential means that it will produce some noise. More often than not, this noise will be more prominent when the unit is first installed, but will drop-off with use.

Q: Can I do anything to quieten down my plate-type LSD?

A: First and foremost we recommend the use of a good quality oil like Millers. Some units will be noisier than others depending on the driveshaft/halfshaft loadings, however we have found that correct alignment of the CWP is vital in the reduction of the clonking noises that can be associated with a plate-type LSD. If the CWP isn't set up correctly, you are essentially forcing pre-load onto the plates. Installing sintered plates will also significantly reduce the noise produced. Many diffs are noisiest when first installed, but the noise will significantly reduce with use.

Q: Is there a running-in procedure for my plate-type LSD?

A: Our best advice is install the unit with a good LSD oil, such as Millers, then straight away put it to work. If you have the space carry out some figure of 8's and lots of tight turns with as much throttle-load as you can. Your LSD will quickly 'settle in' and work at its best. It's best practice, and our recommendation, to replace the oil with fresh after around 30 miles of driving.

Q: How often do I need to get my plate-type LSD serviced?

A: It does depend on the type of use it is getting. Units that see road and track day use can go for years and years, and still outperform other LSD types. The rule of thumb is if you feel like the performance has dropped, get it serviced. Very generally, if the unit gets a heavy amount of motorsport use, it is good practice to service the unit at the start of every season.

Q: Will sintered plates quieten down my plate-type LSD?

A: Yes. They will also enhance the performance of the unit and enable it to perform longer without requiring a service.

Q: Can 3J Driveline install a plate-type LSD for me?

A: Yes. Contact us for more details.

TORQUE BIASING LSD FREQUENTLY ASKED QUESIONS

Q: Will a torque biasing LSD be noisy?

A: If installed correctly, a torque biasing LSD will produce virtually no additional noise.

Q: Does a torque biasing differential ever lock?

A: No. If, for example, a tyre loses contact with the ground during the weight transfer generated by cornering, it will effectively behave like an open diff until it makes contact with the ground again. Although experienced drivers can manage this using the brakes.

Q: Is a torque biasing differential suitable for RWD cars?

A: A torque biasing LSD can be used in both FWD and RWD format. Although its design lends itself to being ideally suited to front-drive applications.

Q: Do I need to use a special oil with a torque biasing LSD?

A: No. Although we always recommend a good quality oil such as Millers.

Q: Will I need to service my torque biasing LSD?

A: The 3J NXG Fast Road torque biasing differential is a fit and forget unit.

Q: Is there a running in procedure for a torque-biasing LSD?

A: We recommend moderate driving for the first 25 miles. However the unit is assembled using lubricants and so is ready for use directly after being installed.

Q: Do I need to modify my transmission in any way to install a torque biasing LSD?

A: Unless otherwise stated, the unit is a direct replacement for the factory differential. On occasion, where factory castings vary, there may be the requirement for a small amount of material relief where not normally expected.

3J LSD RUNNING IN PROCEDURE

To ensure optimum operation and lifespan, it's important that your 3J Driveline Limited Slip Differential is correctly installed and run in.